Case Studies

Customer Gains 6-12% Cost Reduction from Acme’s Lean Manufacturing Benefits

Customer Challenge Many of Acme’s customers encounter cost pressures as they strive to stay competitive in their markets. Since most OEM’s products have more than 50% of their costs generated by the material, parts, and assemblies they purchase, they are very dependent on their supply chain to not only control their costs, but also find... Continue reading→

Product Development Ensures Critical Delivery Performance

Customer Challenge An existing customer was encountering problems procuring a peripheral piece of equipment that was required for shipment with their own product. If the assembly was not available when needed, the customer could not ship as required to their customers. Unable to influence the company that made the peripheral equipment to deliver to their... Continue reading→

New Company Launches Through Joint Product Development Process

Customer Challenge Veterans in the oil and gas industry wanted to launch a new company providing service parts for that industry. While they had expertise in the application of the service parts, they needed a strategic partner to help them develop drawings and manufacturing processes for the many parts that would make up a whole... Continue reading→

Facilitating Growth by Conserving Customer Resources

Customer Challenge An OEM customer was limiting its growth because it was focused on maintaining its current parts and was not able to apply enough time to new parts and projects. When orders came in over their capacity, the OEM outsourced to suppliers who needed significant support from them to supply engineered processes and material... Continue reading→

Full-service partnership Grows Customer Sales by 75%

Customer Challenge A customer in the Oil and Gas industry seeking to capitalize on a high-potential market opportunity came to Acme to develop and manufacture a complex, high precision product that needed exceptional speed-to-market in order to capture a $24 million sales opportunity. Besides a short timeframe, the project required that Acme machine a very... Continue reading→

High Impact Strategic Partnership Results in 110% CAG

Customer Challenge A start-up company offering high-pressure flow control equipment used in oil and gas applications had to develop a strategy for manufacturing its products. The company’s management need to answer the question: “Should we use available human and capital resources to vertically integrate our own manufacturing facility, or utilize a strategic partner?” The decision... Continue reading→

Business Model Change Focuses Business on its Core Strengths Leading to 23% Growth

Customer Challenge An OEM that produced very large equipment machined its own complex, precision parts, but realized that although it had a world-class product it did not have a world-class machining operation. The OEM’s analysis of their business highlighted the tradeoffs they faced: invest capital into upgrading their machine tools and manufacturing organization or put... Continue reading→

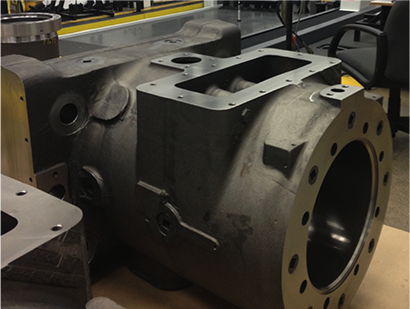

Bringing Order to Chaos

Customer Challenge An OEM prospect had an important part family component of its product line that were not performing and causing major problems. The castings had excessive porosity and lack of stock and the machining supplier was not delivering on time or with the necessary quality to keep the company’s production lines running on schedule. ... Continue reading→

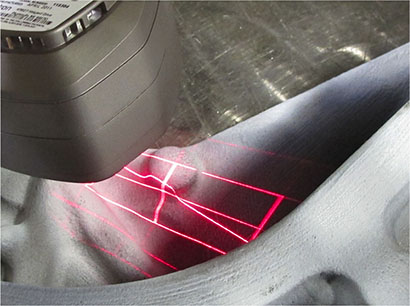

A Laser Focus on Service

Customer Challenge A manufacturer of large fluid handling equipment was moving a suite of valve castings from one foundry into another as part of a strategic initiative to launch a new product. Critical to the process were the rapid transfer of patterns and the launch of new patterns. Timing became compromised during the qualifications phase... Continue reading→

Scaling up to Meet Market Opportunities

Customer Challenge When an ACME customer introduced a new product family into the market, it found that demand far exceeded capacity of the supply base. Our customer knew that a substantial amount of additional business could be generated if availability of the product family could be increased. The part family required precision machining of large... Continue reading→

Data Duel

Customer Challenge ACME provides precision machining of power cylinders for a manufacturer of heavy equipment used in petroleum pipeline management. After machining by ACME, these power cylinders proceed to another supplier who provides plating and honing services. After honing, the supplier took measurements of the main bore to a mounting face, and found that the... Continue reading→

Cross-Divisional Success

Customer Challenge As a result of an ongoing and successful relationship, one of Acme’s oil and gas customers referred our company to its division that manufactures products used in drilling applications. A great supplier was needed to provide the capacity required for the division’s growth and fulfillment of year-end commitments. BEYOND PRECISION SOLUTION Acme quickly gathered... Continue reading→