Acme Industries sets the standard for machining excellence

We focus on offering innovative solutions that enhance product functionality while achieving significant savings in both cost and production time.

Our ServicesWho we are

About Us

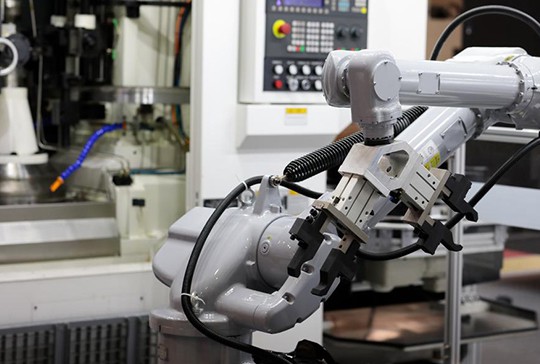

Acme Industries has set the industry-standard for excellence and precision in manufacturing since 1948. For over seven decades, we have been at the forefront of the manufacturing industry, providing unparalleled services including:

- CNC Milling

- CNC Turning

- Assembly

- Supply Chain Management

- Engineering Services

Why Choose Us

Why Choose Acme Industries?

Strategic Location for Efficient Delivery: Our Elk Grove Village facilities located in the largest industrial park in the nation provide easy access to major transportation networks, ensuring timely delivery as well as an abundance of value added partners.

- Comprehensive Service Offerings

- Advanced Technology and Expert Team

- Adjacent to largest concentration of casting and forging suppliers in US

- Customized Solutions for Diverse Industries

- Customer-Centric Approach

Benefits of Collaborating with Acme Industries

- Enhanced Product Functionality

- Cost Optimization

- Well positioned for onshoring

- Engineering Department Support

- Customized Solutions for Unique Challenges

- Technological Advancements

- Strategic Process Development

- Sustainability Considerations

- Rapid Prototyping and Feedback

Extended Benefits of Choosing Acme Industries

- Customized Solutions

- Technical Expertise

- Efficient Production

- Innovative Techniques

- Comprehensive Service

- Sustainability Focus

- Global Standards Compliance

Featured Case Studies

Full-service partnership Grows Customer Sales by 75%

A customer in the Oil and Gas industry seeking to capitalize on a high-potential market opportunity came to Acme to develop and manufacture a complex, high precision product that needed exceptional speed-to-market in order to capture a $24 million sales opportunity.

Bringing Order to Chaos

An OEM company chose Acme Industries to take on tier 1 responsibility for the part family, help choose a new foundry to supply the castings and bring them into production.

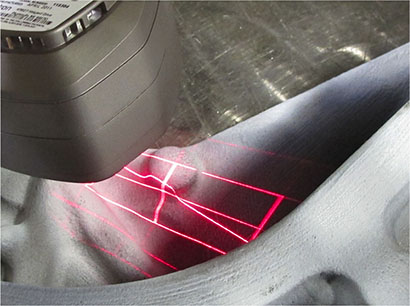

A Laser Focus on Service

A manufacturer of large fluid handling equipment was moving a suite of valve castings from one foundry into another as part of a strategic initiative to launch a new product. Critical to the process were the rapid transfer of patterns and the launch of new patterns.

Product Innovation Increases Market Opportunity

One of Acme’s customers had a product that in many respects was a commodity compared to its competitors’ products. Its design was almost exactly the same and its field performance was comparable.

Quality Assurance

Quality Assurance and Vendor Selection

Acme’s Quality Assurance department is committed to providing unrivaled quality and excellence. Our vendor qualification process is rigorous and thorough, ensuring that only the highest-quality suppliers and partners are selected. This process involves comprehensive evaluations of potential vendors' capabilities, financial stability, and adherence to quality standards. By being proactive in our vendor selection, we ensure that our supply chain is robust, reliable, and capable of meeting the high standards our clients expect.

Learn More

Benefits of Partnering with Acme Industries

- 01 Risk Reduction

- 02 Enhanced Supply Chain Partners

- 03 Overhead Alleviation

- 04 Focus on Core Business

Featured Case Studies

Full-service partnership Grows Customer Sales by 75%

Customer Challenge A customer in the Oil and Gas industry seeking to capitalize on a high-potential market opportunity came to Acme to develop and manufacture a complex, high precision product... Continue reading→

Bringing Order to Chaos

Customer Challenge An OEM prospect had an important part family component of its product line that were not performing and causing major problems. The castings had excessive porosity and lack... Continue reading→

A Laser Focus on Service

Customer Challenge A manufacturer of large fluid handling equipment was moving a suite of valve castings from one foundry into another as part of a strategic initiative to launch a... Continue reading→