|

| |

| A Letter from Warren Young, President & CEO |

|

As many of you know, manufacturing capacity in the US was reduced by 5.4% over the past two and half year period from April 2008 to November 2010. Since the end of last year, it has begun to increase and is showing signs of recovery. As noted in an article in The Economist (March 12, 2011) entitled Rustbelt Recovery, American factories are coming back to life. Against all odds, US manufacturing is on the upswing and has driven 18% of private job gains since December 2009.

As an industry thought leader, Acme Industries was tapped by The Economist as well as Fortune Magazine for our insights into the recovery of US manufacturing. As noted in our interview, we are experiencing an uptick in business. With orders, backlogs, and shipments up significantly in 2011, our company is fully participating in the recovery. Although we have seen increases across all of our customer industries, we are experiencing particularly strong growth in oil & gas, as well as mining equipment.

When asked by the media, “what is fueling the recovery of US manufacturing,” Acme shared that many original equipment manufacturers (OEM’s) are facing new challenges. As the world experiences economic and political change, global supply chain strategies are being negatively impacted. For instance, in China, costs are rising and there are increasing capacity constraints. And, in Mexico, there are valid concerns about the safety of workers and business visitors.

Read More >

|

|

|

| Measuring Success: Building Strategic Relationships |

|

One party wins. The other party loses. This approach has historically defined the customer/supplier relationship in manufacturing.

At Acme Industries, we have evolved away from this typical industry practice. Rather than putting an emphasis on winning at the expense of our customer, we create value through integrity, trust, outstanding performance, and commitment to our customers’ success.

Our core values and unwavering commitment create strategic relationships that drive bottom-line results for our customers; many of whom have strong incentives to grow their businesses but are limited by available resources. By strategically aligning with our customers, Acme collaborates to remove barriers and open doors for successful product development and innovation.

From cost reduction sharing to other win-win collaborations with customers, Acme Industries brings its Beyond Precision philosophy to bear. To read more about how our customers benefit from our thinking, visit our website and learn how our strategic relationships produce significant bottom-line results for our customers.

|

|

|

| An Engineering Perspective: Angelo Castellucci |

|

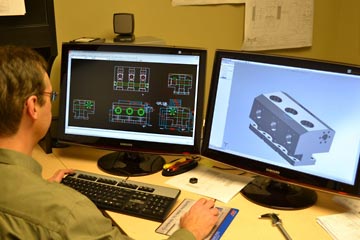

Angelo Castellucci is the Manufacturing Engineering Manager at Acme Industries. Angelo joined Acme in December 1998 as a Senior Manufacturing Engineer. He manages a team of four manufacturing engineers that process all of Acme’s new work that comes in. Since arriving at Acme, he has been a major contribution to the new culture of fast pace, rigorous and innovative thinking in the Engineering Department.

How does Acme’s engineering team go Beyond Precision?

Acme’s Manufacturing Engineering Department goes Beyond Precision by identifying new opportunities and technologies for superior solutions and cost reduction to benefit our customers. Acme serves its customers as their reliable manufacturing partner throughout the lifecycle of their most critical parts and analyzes the best solutions for manufacturability, cost savings, and efficiencies.

How have you implemented strategic solutions for your customers?

One example, among many, was when a new customer approached us with a limited knowledge of machining castings. They needed assistance on design for manufacturability and help on recognizing features that would impact the cost of machining. We offered our strategic input and implemented a solution that not only decreased the cost of the casting, as well as the machining cost, but also made some features more easily accessible in the assembly process. Our team was there to help on every phase of designing and manufacturability, and the project was well-received by the customer.

From an engineering perspective, what sets Acme apart from competition?

From casting designs, scanning, final prints, 3D modeling, and up to the finished machined product, our versatility has no boundaries. Acme’s staff exhibits versatility and experience, having backgrounds in designing, metallurgy, structural analysis, gear industries, and much more. Not only does Acme have the solid manufacturing know-how, but we also deliver a high degree of technical skills that help satisfy our customers’ needs.

|

|

| Acme’s Year in Review |

|

The end of April 2011 marked the completion of Acme Industries’ fiscal year with favorable results. Thanks to our diversified customer base, we showed modest year-on-year growth and continued to exhibit resilience in the face of an uncertain economy.

Over the past year, Acme Industries added five new strategic relationship customers in four industries: oil & gas, underground mining, power generation, and heavy duty drive train. We look forward to working with our partners in these industries and are excited to grow with them.

In addition, we expanded our footprint with existing customers. As these ongoing relationships continue to evolve, our Manufacturing Engineering Department and shop personnel stay very busy processing over 90 new part numbers.

As we look forward to our next fiscal year, we hope to continue to ride the wave of robust manufacturing growth. While it certainly won’t be without its challenges, we are confident that Acme Industries is well positioned to capitalize on our strengths to help our customers continue to grow and succeed. |

|

| © 2011 Acme Industries |

| www.acmeind.com |

|

|

|

|

|

|